The intersection of supply chain and reputational risks has created a perfect storm that poses a potential threat to both an organization’s profitability and brand equity.

Understanding and managing risks within supply chains is already a complex exercise. Supply chain management requires driving efficiency and margin through sourcing strategies, while facing various challenges including natural disasters, cyber threats and geopolitical instability.

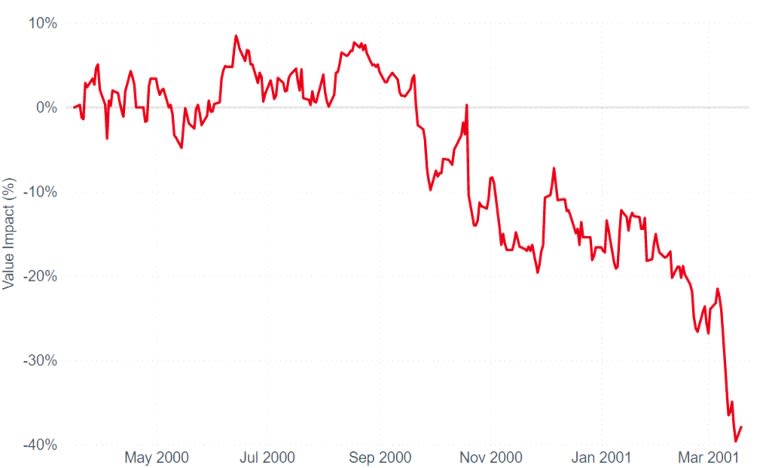

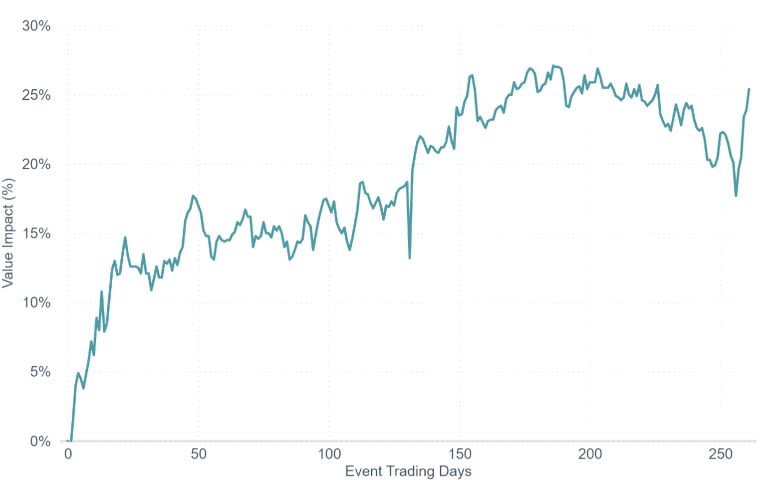

At the same time, risk management must also contend with environmental, social and governance (ESG)-related exposures within the global supply chain. And these can have longer-term reputational impact, which may lead to both loss of stakeholder confidence and shareholder value.

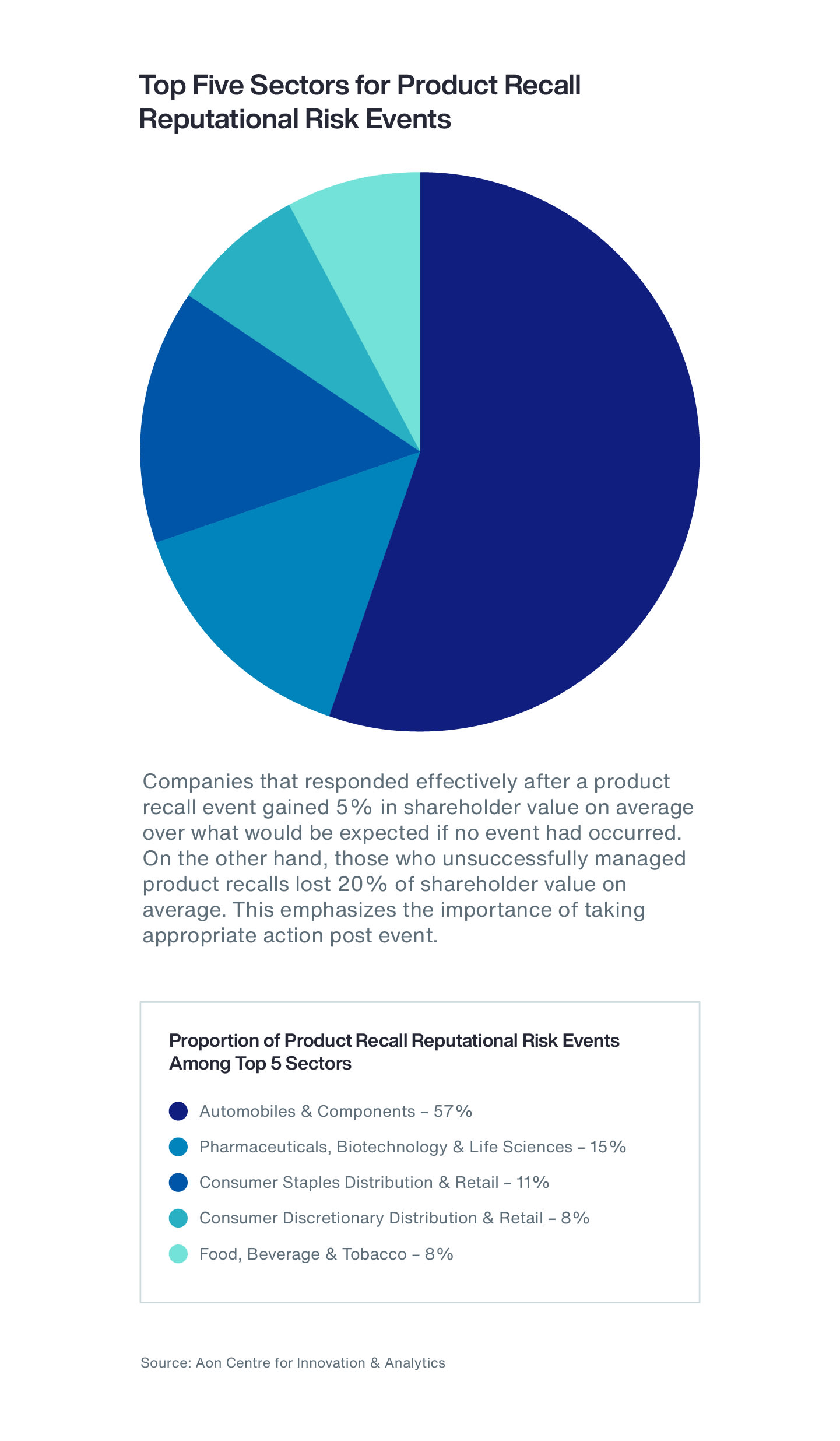

ESG threats can cause downstream effects on supply chains, including product recalls, launch delays and unexpected price hikes, eroding customer confidence and investor trust. Further, these threats are quite common, with 43 percent of organizations experiencing financial loss in the past 12 months due to supply chain risks.