Given these factors, organizations ranked supply chain or distribution failure as the sixth biggest risk they face globally. This necessitates a shift toward fortified, more

strategic long-term supply chain management approaches.

“Companies must prioritize resilience, agility and sustainability in their supply chain strategies to effectively

mitigate risks and capitalize on emerging opportunities,” says Richard Waterer, Aon’s Global Risk Consulting Leader

for Commercial Risk Solutions.

Managing Risks and Building Resilience

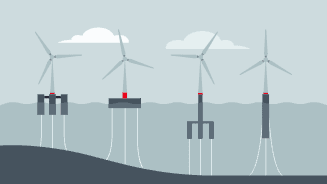

With the recent focus on reliability and quality over cost, reshoring continues to gain traction. It brings greater resilience and certainty to supply chains, ensuring products' quality,

reliability and cost-effectiveness. It also reduces transit times due to geographical proximity and fosters better

collaboration among stakeholders.

Yet, the promise of reshoring must be tempered with a clear assessment of associated risks. “It is crucial for

companies to understand that reshoring does not guarantee a risk-free environment,” says Tom O'Donnell, Aon’s

Practice Leader for Global Logistics. “These changes require careful planning and implementation over time.”

For instance, building in-house production facilities poses significant risks,

including:

- Project delays

- System malfunctions

- Compliance and integrity risks

- Startup delays

- Change management challenges

- Local planning issues

- Construction-related risks